Spray forming technology

Spray forming, English name: spray forming; Spray forming is a process that uses high-pressure inert gas to atomize the alloy liquid stream into small droplets, fly and cool under high-speed airflow, and deposit into a blank before it is fully solidified. It has various advantages of rapid solidification techniques such as obtaining materials with fine grains, uniform microstructure, and being able to suppress macro segregation.

It is a new process technology that integrates metal melting, liquid metal atomization, rapid solidification, and spray deposition molding into a metallurgical operation process to produce metal material products. It plays a significant role in developing new materials, reforming traditional processes, improving material performance, saving energy consumption, and reducing environmental pollution. This method was first patented by Osprey Metals in the UK (1972), so it is commonly known internationally as the Osprey process. Massachusetts Institute of Technology (MIT) in the United States, also known as liquid dynamic compaction (LDC) due to the use of ultrasonic atomization technology spray.

Due to the effect of rapid solidification, the obtained metal material has uniform composition, fine microstructure, no macrosegregation, and low oxygen content. Compared with traditional casting forging process and powder metallurgy process, it has short process flow, simplified process, and high deposition efficiency. It is not only an advanced technology for making blank, but also developing into a process for directly manufacturing metal parts. It has become a hot spot in the development and application of new materials in the world.

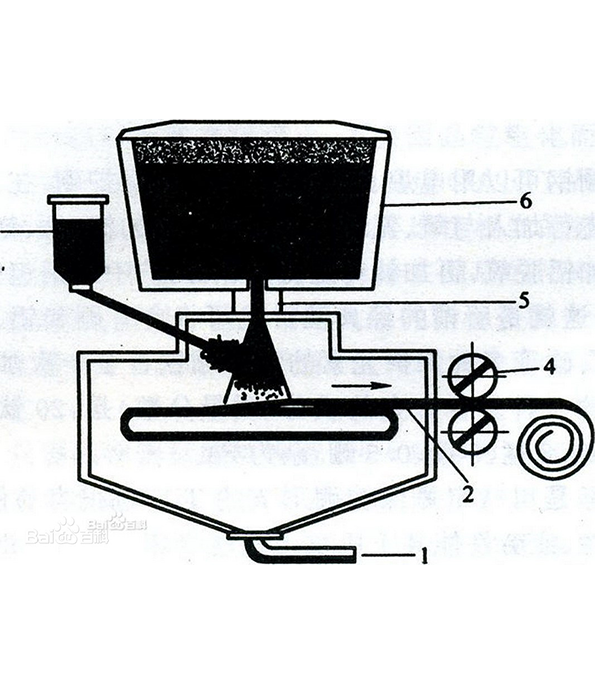

The principle of spray forming is shown in Figure. Similar to the atomization method, the molten metal or alloy liquid is first atomized into small droplets with nitrogen or argon, and then directly sprayed and deposited into preforms without being solidified into powder, with a relative density of over 96%. After subsequent hot processing (forging, rolling, extrusion, or hot isostatic pressing), a fully dense product is formed. Due to the rapid solidification effect, this spray formed product has a refined crystal structure, uniform composition, and no macrosegregation. It almost has the advantages of powder metallurgy products, but it can eliminate the processes of milling, screening, pressing, and sintering, reducing production costs.