ESR M2 Cobalt High Speed Tool Steel

M2 Cobalt high-speed steel increases the content of Co element on the basis of M2 to improve its red hardness. Specially for planer knife with wear resistance.

SPECIFICATION

| SIMILAR STEEL GRADES | ||||||

| National Standard | Manufacturer Standard | |||||

| GB | AISI | DIN | JIS | Erasteel | Bohler | Hitachi |

| W6Mo5Cr4V2Co2 | M2 Modify | 1.3343 | SKH51 | - | - | - |

|

Chemical composition % |

||||||||||

| C | Si | Mn | P ≤ | S ≤ | Cr | W | Mo | V | Co | etc. |

| 0.9 | 0.38 | 0.35 | 0.03 | 0.003 | 4.1 | 6 | 4.8 | 1.8 | 1.4 |

|

|

Characteristics |

|||

| Annealed Hardness HB | Heat Treatment Temperature ℃ | Tampering HardnessHRC | |

| Hardening | Tempering | ||

| 255 | 1200-1220 | 550 | 63-67 |

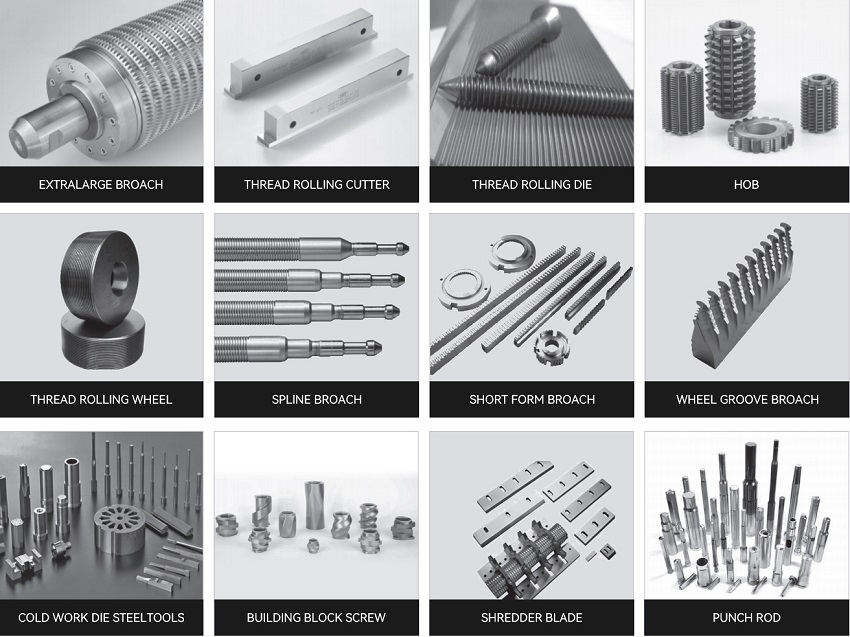

Applications

Broaches and Reamers Cold Forming / Coining Fine Blanking, Stamping, BlankingGear Cutting, Shaving and Shaping Tools Injection Components Oth. Automotive components (Turbochargers, PistonRings, Sensors, etc.)

Powder Pressing Rolling Shearing / Machine Knives

Special Cutting Tools Standard Parts (Molds,Plates, Pins, Punches) Twist Drills and Taps Wear parts Thread rolling Blades for SawingMachines;Holemaking, Threading tools, Milling tools, Cutting tools, Broaching tools, Sawing tools - machine saw blades, band saw edges, Stamping dies - punching rods, Fine blanking dies, Grease nozzle oil pumps, Vane (pump)

Supply Form

|

|