H12/1.2602 Hot Work Die Tool Steel

H12 steel is a type of hot-work tool steel with high chrome and vanadium content. It is known for its excellent toughness, wear resistance, and thermal conductivity, making it suitable for use in high-temperature applications such as forging, aluminum die-casting, and extrusion. H12 steel is also resistant to thermal fatigue and can maintain its strength even at high temperatures. It can be hardened by heat treatment and has good machinability.

SPECIFICATION

| SIMILAR STEEL GRADES | ||||||

| National Standard | Manufacturer Standard | |||||

| GB | AISI | DIN | JIS | Erasteel | Bohler | Hitachi |

| *3Cr5WMoSiV | H2 | 1.2602 | SKD62 | - | W321/W320 | - |

|

Chemical composition % |

||||||||||

| C | Si | Mn | P ≤ | S ≤ | Cr | W | Mo | V | Co | etc. |

| 0.35 | 1.10 | 0.30 | 0.028 | 0.02 | 5.15 | 1.30 | 1.40 | 0.4 | - |

|

|

Characteristics |

|||

| Annealed Hardness HB | Heat Treatment Temperature ℃ | Tampering HardnessHRC | |

| Hardening | Tempering | ||

| 235 | 1020 | 530-560 | 45-53 |

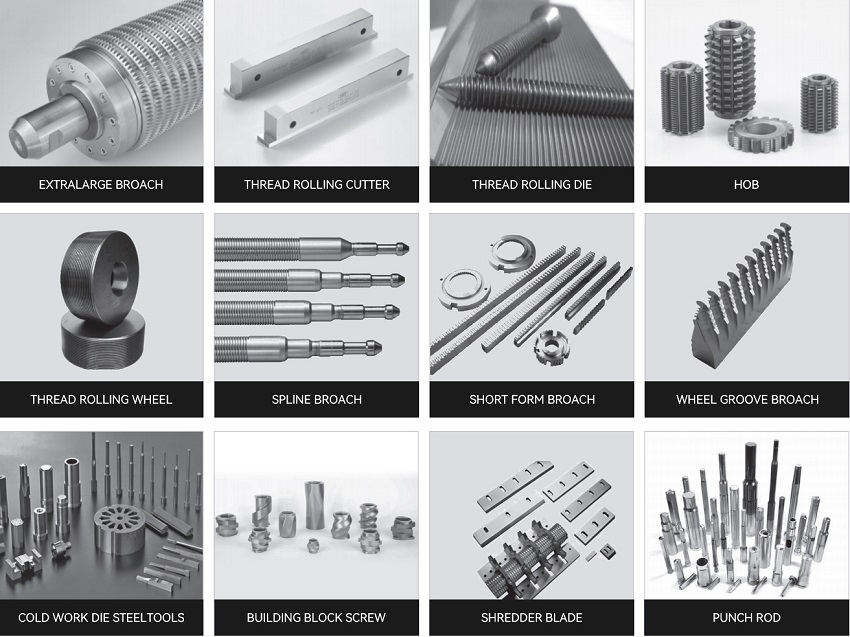

Applications

Mechanical press mold, ejector bar

Supply Form

|

|