ESR M4 SKH54 High Speed Tool Steel

M4 high-speed steel is a popular, high-performance tool steel that is commonly used in cutting and drilling applications. It is designed to handle high temperatures and severe mechanical stresses, making it ideal for demanding machining operations.

SPECIFICATION

| SIMILAR STEEL GRADES | ||||||

| National Standard | Manufacturer Standard | |||||

| GB | AISI | DIN | JIS | Erasteel | Bohler | Hitachi |

| *W6Mo5Cr4V4 | M4 | PMHS6-5-4 | SKH54 | EM4/ASP2004 | S693/S692 | XVC11 |

|

Chemical composition % |

||||||||||

| C | Si | Mn | P ≤ | S ≤ | Cr | W | Mo | V | Co | etc. |

| 1.3 | 0.38 | 0.35 | 0.03 | 0.003 | 4.1 | 5.5 | 4.5 | 3.85 | - |

|

|

Characteristics |

|||

| Annealed Hardness HB | Heat Treatment Temperature ℃ | Tampering HardnessHRC | |

| Hardening | Tempering | ||

| 255 | 1200-1220 | 550 | 63-66 |

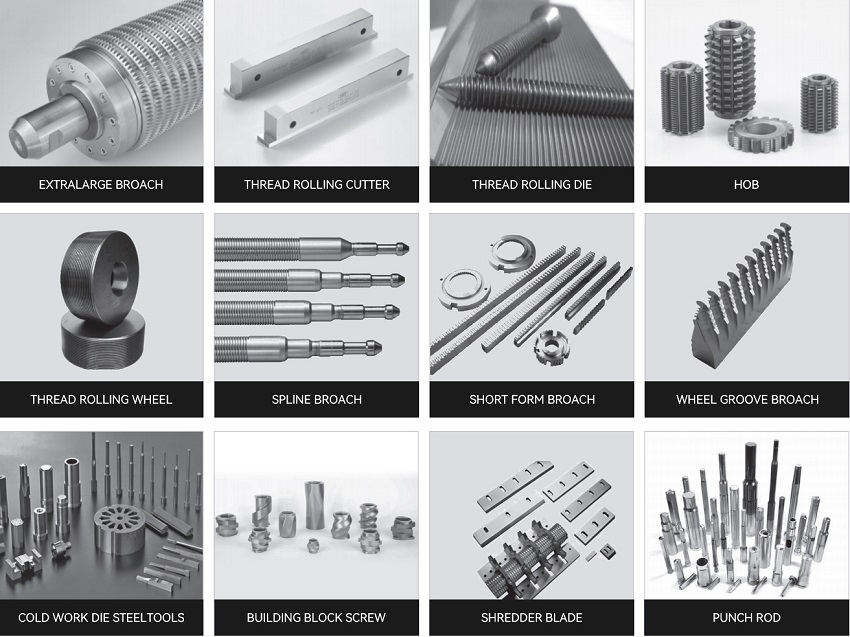

Applications

Broaches, Cold work, Cutting Tools, Gear Cutting Tools, Taps and dies;High wear resisting cutters and cold mould

Supply Form

|

|